Drone crack survey service | Advanced technology for building safety

Modern building inspection solutions

We provide building structure inspections using advanced drone technology to detect damages such as cracks, leaks, and defects without sending people to heights, reducing risks and saving costs.

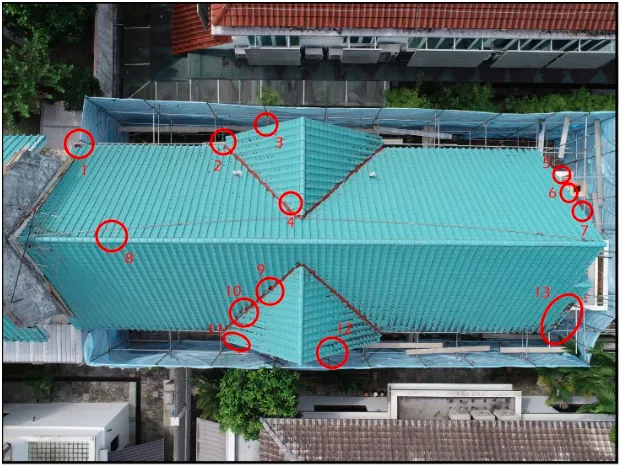

Post-disaster crack inspection using drones.

Inspect structural damage of buildings using drones.

"Identify issues to prevent further damage."

Drone solutions that enable large warehouse owners to quickly and safely inspect structures after disasters.

Drone inspection process

Plan the inspection.

Survey the area, select appropriate equipment, and check local regulations.

Define the mission.

Use software (e.g., Hammer Hub) to plan flight paths, altitude, and image capture.

Conduct the flight.

Follow the plan and collect data using visual and thermal cameras from all angles.

Process data.

Analyze collected data to identify problem areas such as cracks or moisture.

Deliver results.

Prepare result reports and share with stakeholders for decision-making.

Our drone inspection technology

High safety standards

Reduce risks from climbing or entering hazardous areas.

Cost-effective

Reduce costs from using temporary structures or traditional methods.

Fast and efficient

Quick inspections to help resolve issues promptly.

Clear data

Capture high-quality images and data, including thermal camera data.

Comprehensive services to meet all your needs

1. Exterior building inspection

2. Identify leaks and moisture.

3. Post-disaster inspection

4. Track project progress.

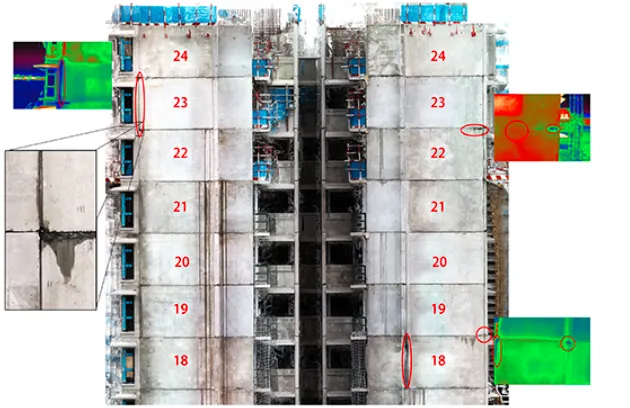

Using thermal cameras for drone inspections.

Advantages of Thermal Imaging Technology

Thermal cameras enable drones to detect temperature differences on building surfaces, revealing hidden issues such as cracks, moisture, or energy loss.

Practical applications

Ideal for inspecting roofs and walls to detect moisture or cracks that may lead to future damage, helping to quickly identify areas needing repair.

Usage examples:

Wall inspection using thermal cameras.

Detect problematic areas.

The image shows temperature differences, with red or yellow areas indicating higher temperatures, which may result from cracks or moisture.

Zoomed-in image of cracks.

Zooming in on suspicious areas reveals cracks clearly, which are often invisible to the naked eye.

Analyze results.

Using drones and thermal cameras helps detect hidden damages and plan repairs efficiently.

Our work process

Consult and plan.

Discuss to understand needs and plan flight paths covering all points.

Inspect with drones.

Use drones to capture images and videos from all angles.

Analyze and assess.

Collect data obtained from drone inspections to analyze actual conditions and assess results in detail, helping to understand the situation and accurately determine corrective actions.

Deliver results and provide recommendations.

Provide reports with recommendations for corrective actions.

Reasons to choose drone inspection services.

High safety standards

Reduce risks from working at heights by eliminating the need for people to climb for inspections.

Save budget.

No need for temporary structures, reducing labor and equipment costs.

Fast and efficient

Inspect large buildings in just a few hours instead of several days.

High-quality data.

Use high-resolution cameras and thermal technology for clear data.

Access hard-to-reach areas.

Able to inspect areas that are difficult for humans to reach.

Benefits for warehouse owners.

Reduce costs.

No need for temporary structures or large inspection teams, significantly reducing the budget.

Fast inspection.

Immediate inspection helps quickly assess damage and plan repairs.

Enhance safety.

Reduce hazards for the team, especially in high-risk areas after disasters.

Minimize downtime.

Identify and resolve issues quickly, helping your business continue smoothly.

Tools used for inspection.

Next-generation intelligent drones.

Equipped with obstacle avoidance systems, capable of operating in confined spaces.

Thermal camera

Detect leaks and moisture invisible to the naked eye.

4K high-definition camera

Capture clear images of small cracks.

3D modeling software

Create 3D images of buildings for precise analysis.

Laser sensor

Measure the size and depth of cracks accurately.

3D modeling software

Create 3D images of buildings for precise analysis.

Laser sensor

Measure the size and depth of cracks accurately.

Results you will receive

Customer groups served.